While the primary purpose of the facility is to provide fabrication capability to NTCore staff, we welcome CBS faculty, post docs, and graduate students once they have completed safety training. The NTCore shop is not intended for undergraduate use. Harvard offers access to many other fabrication spaces for this purpose. Limited exceptions will be considered when directly requested by a faculty lab head.

Access to the shop is HUID swipe card controlled. Failure to behave in a safe, respectful and courteous manner will result in removal of this privilege.

Please use the shop in a responsible manner, behave safely and encourage safe practice in others, clean up after yourself, don’t remove tools, and be respectful of the needs of all CBS users.

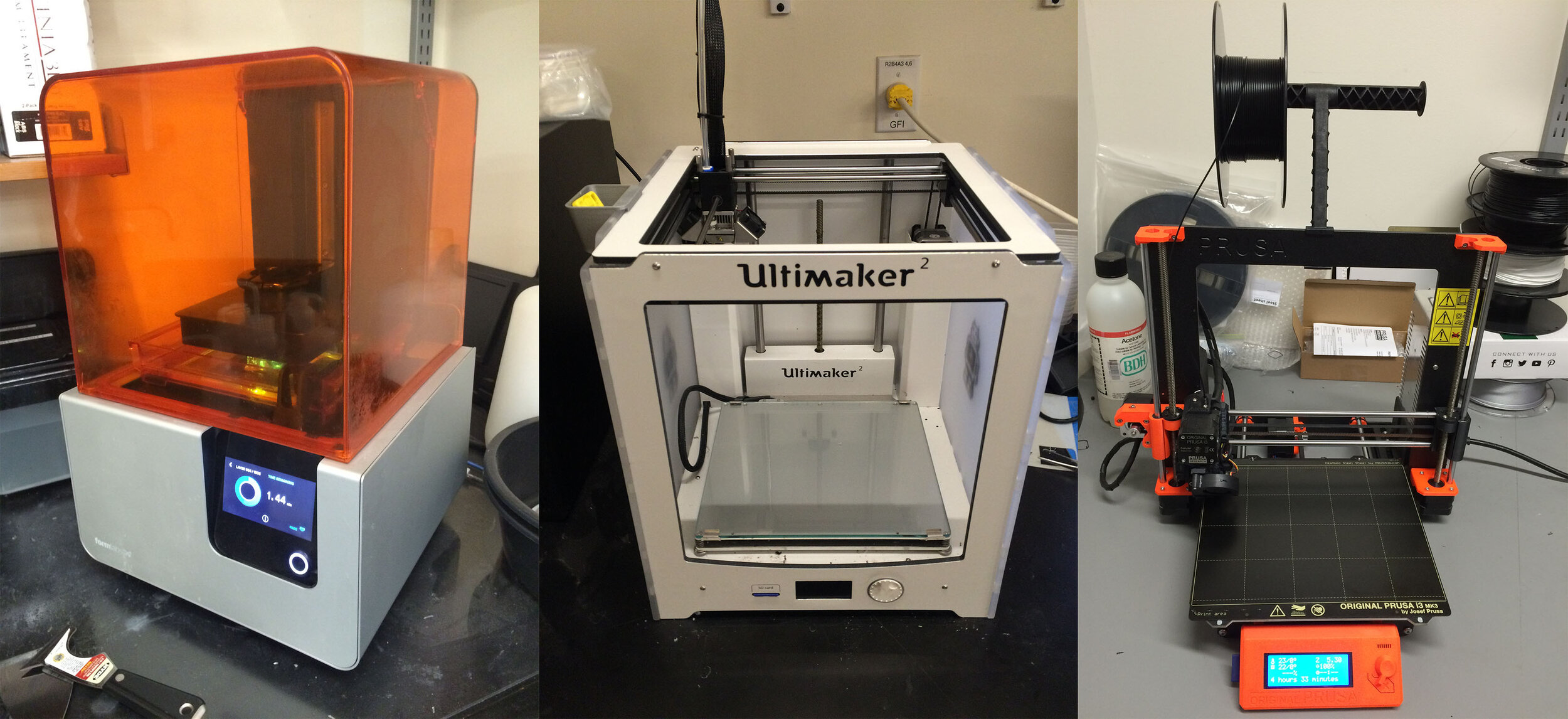

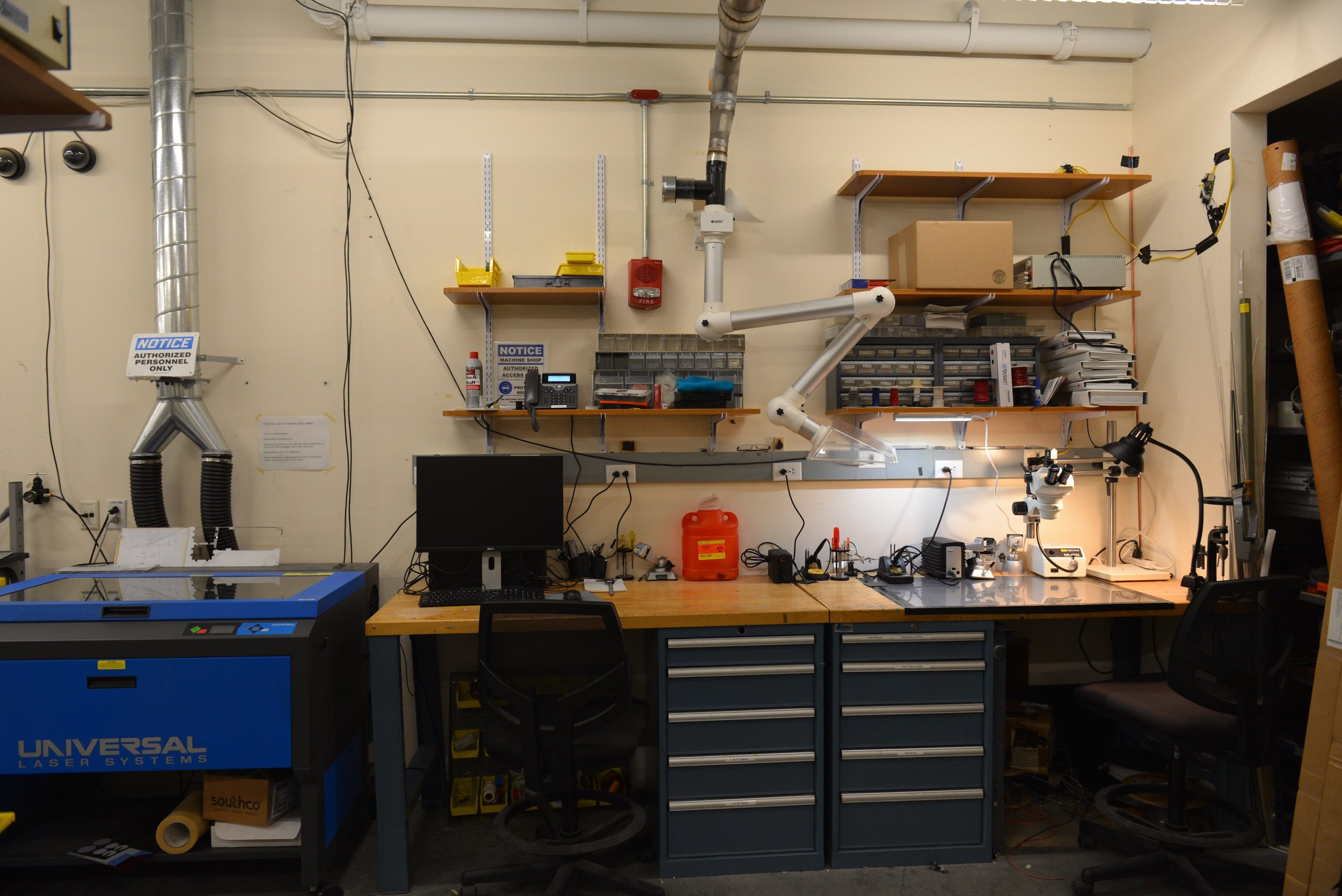

The shop, located in B401 of Northwest Labs, contains a multitude of tools, each requiring specific training. You are only allowed to use tools for which you have been trained by NTCore staff. Training is done one-on-one. Initial requests for access often center around 3D printing, soldering or laser cutting. This is a good way to introduce yourself to us and the shop. After you begin working in the shop, you may want to request training to learn how to use the thermoformer, micro-welders, drill press, bandsaws, milling machines, lathes, etc. Currently, shop access, training and consultation on design and fabrication are all offered free-of-charge thanks to the generosity of CBS and supporting labs.

Training

To complete your initial safety training you will need to:

Arrange an initial virtual or in-person meeting with NTCore staff to introduce your research needs (recommended, not required)

Read this page and the General Safety Rules. https://www.ntcore.org/safety

Complete online EHS Machine Shop and Makerspace Safety Awareness training (Course ID: EHS-00038725)

Read, sign and have your PI sign the safety waiver form located at: https://www.ntcore.org/s/waiver.pdf

Send us a copy of:

your safety waiver

EHS training certificate

name as it appears on your Harvard ID

last four digits of your Harvard ID number

Training for most tools involves an in-person one-on-one training session that takes on average one hour. Exceptions include:

Laser cutter

Review the online training material. If you have any questions please email us before proceeding.

Complete the EHS Fire Extinguisher training (Course ID: EHS-IHS110)

Arrange a time for in-person testing where NTCore staff will observe your first usage of the tool

Review the online training material. If you have any questions please email us before proceeding. If possible, please share your design with us so we can discuss the best way to meet your needs.

Arrange a training time so NTCore staff can observe and guide your first usage of the tool

Review the online training material. If you have any questions please email us before proceeding. If possible, please share your design with us so we can discuss the best way to meet your needs.

Arrange a training time so NTCore staff can observe and guide your first usage of the tool

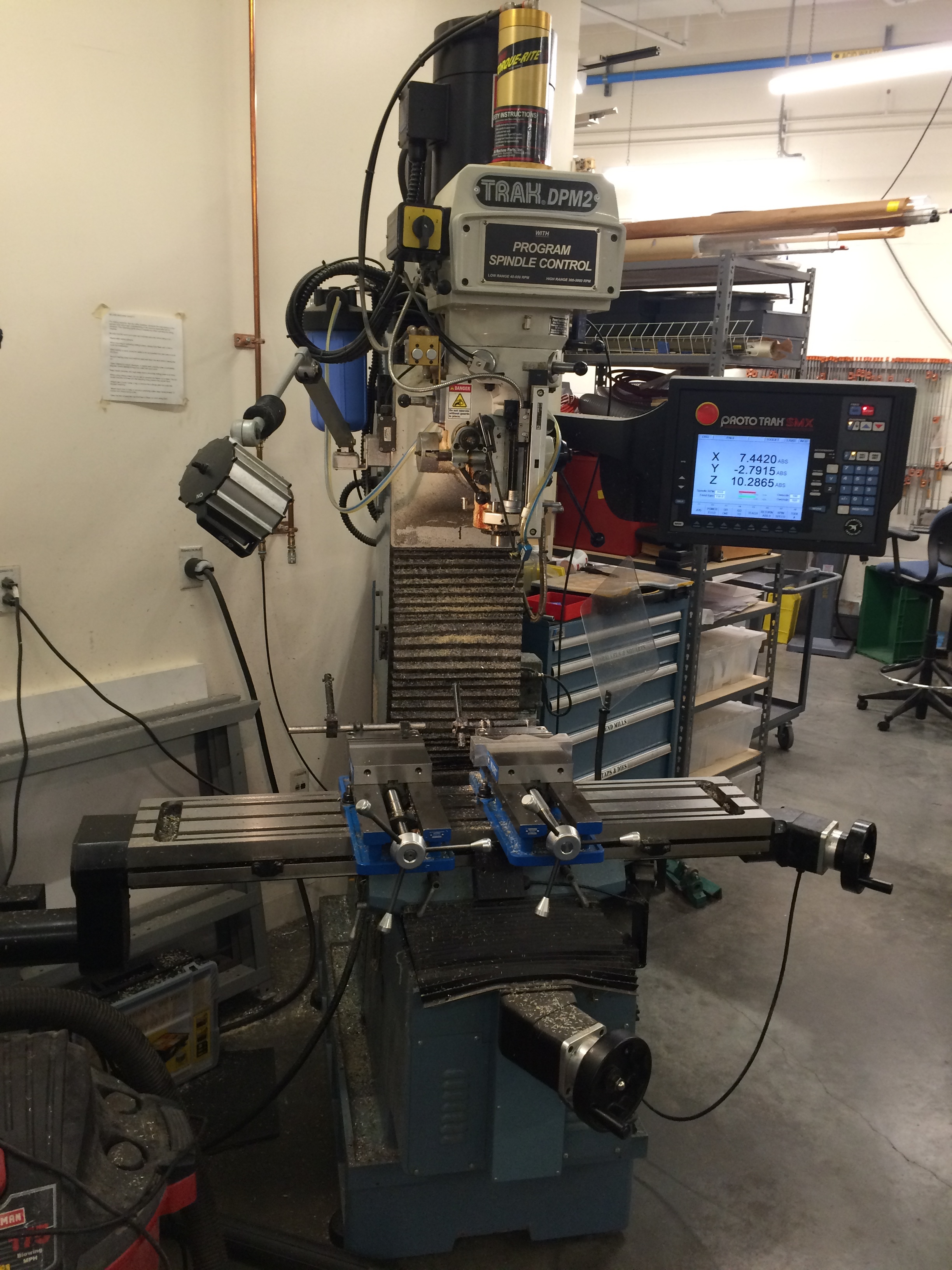

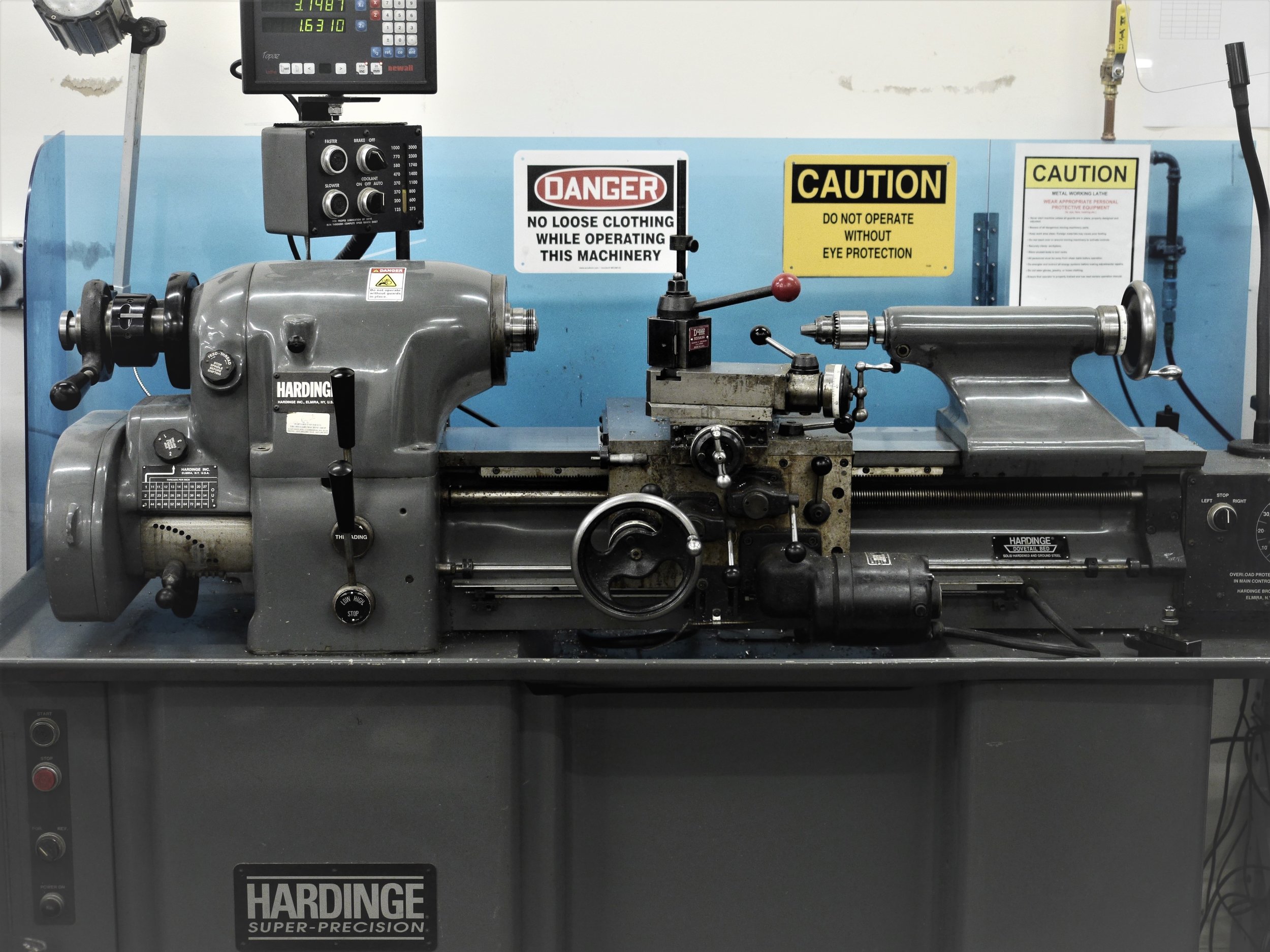

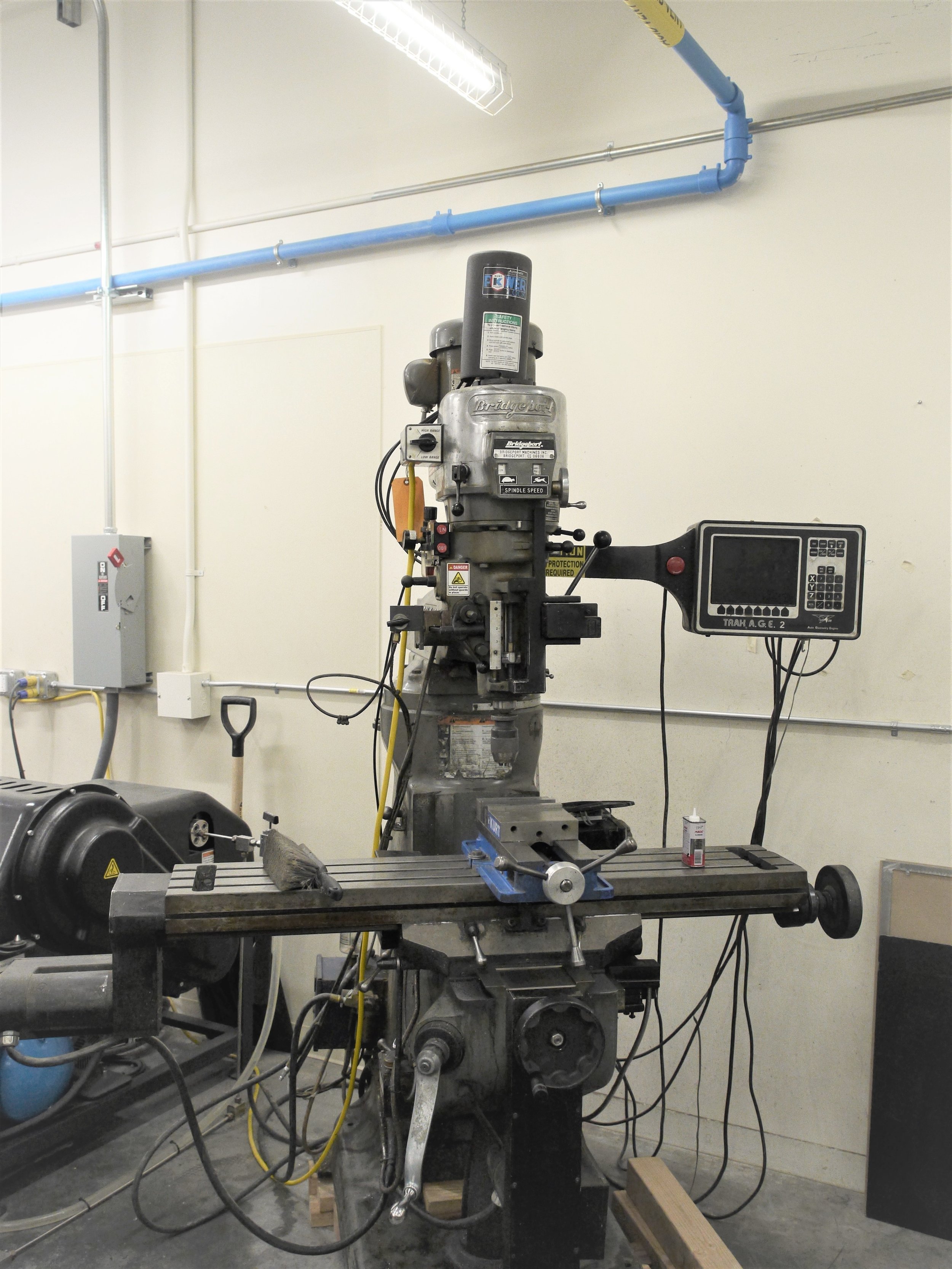

Mill and/or Lathe: requires Full (formerly GREEN) certification in the Harvard Physics SEAS Machine Shop followed by one-on-one training where we will show you the specifics of our machines.

Contact us for training and access.

Equipment

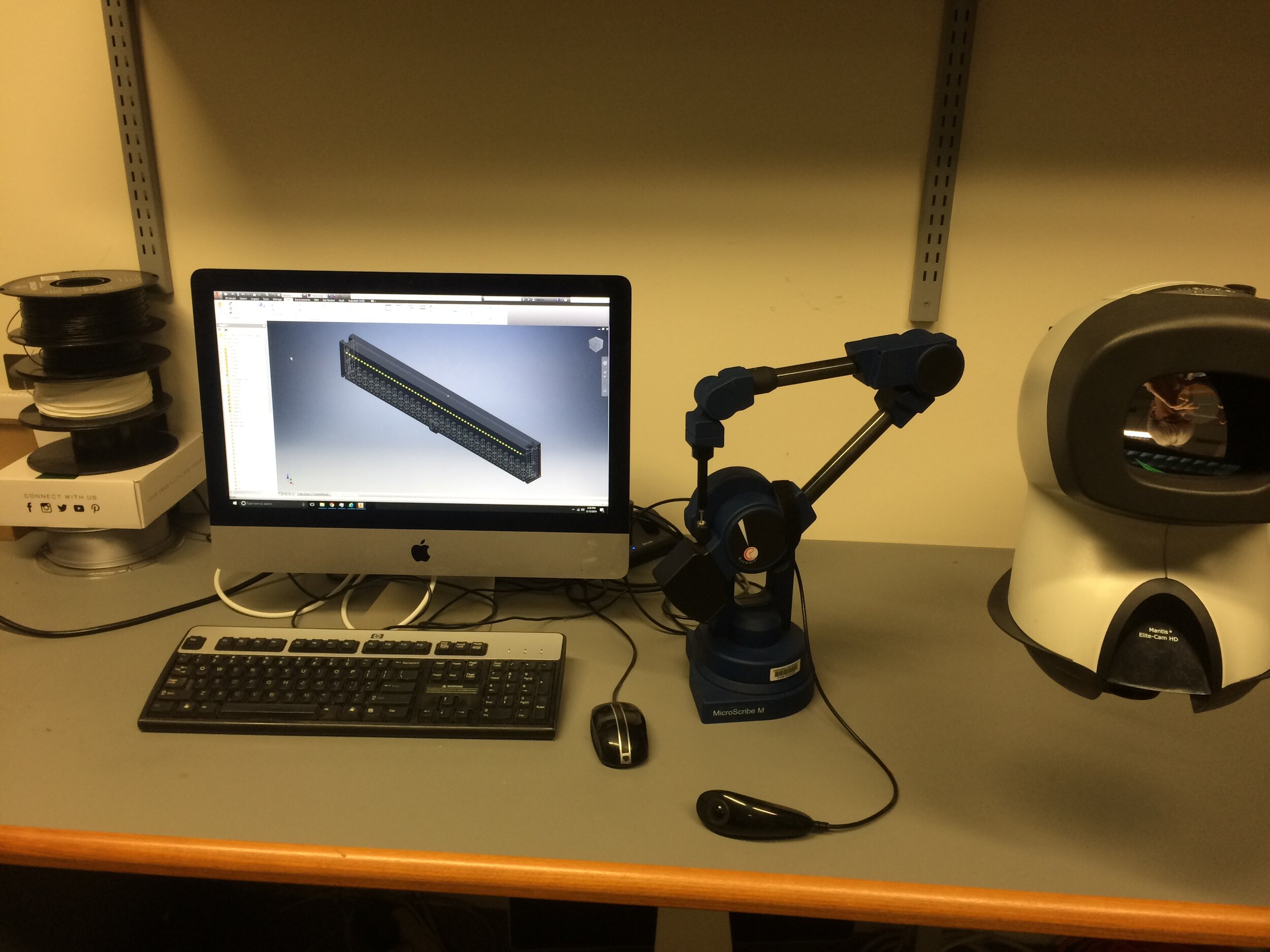

CAD workstations

CMM arm

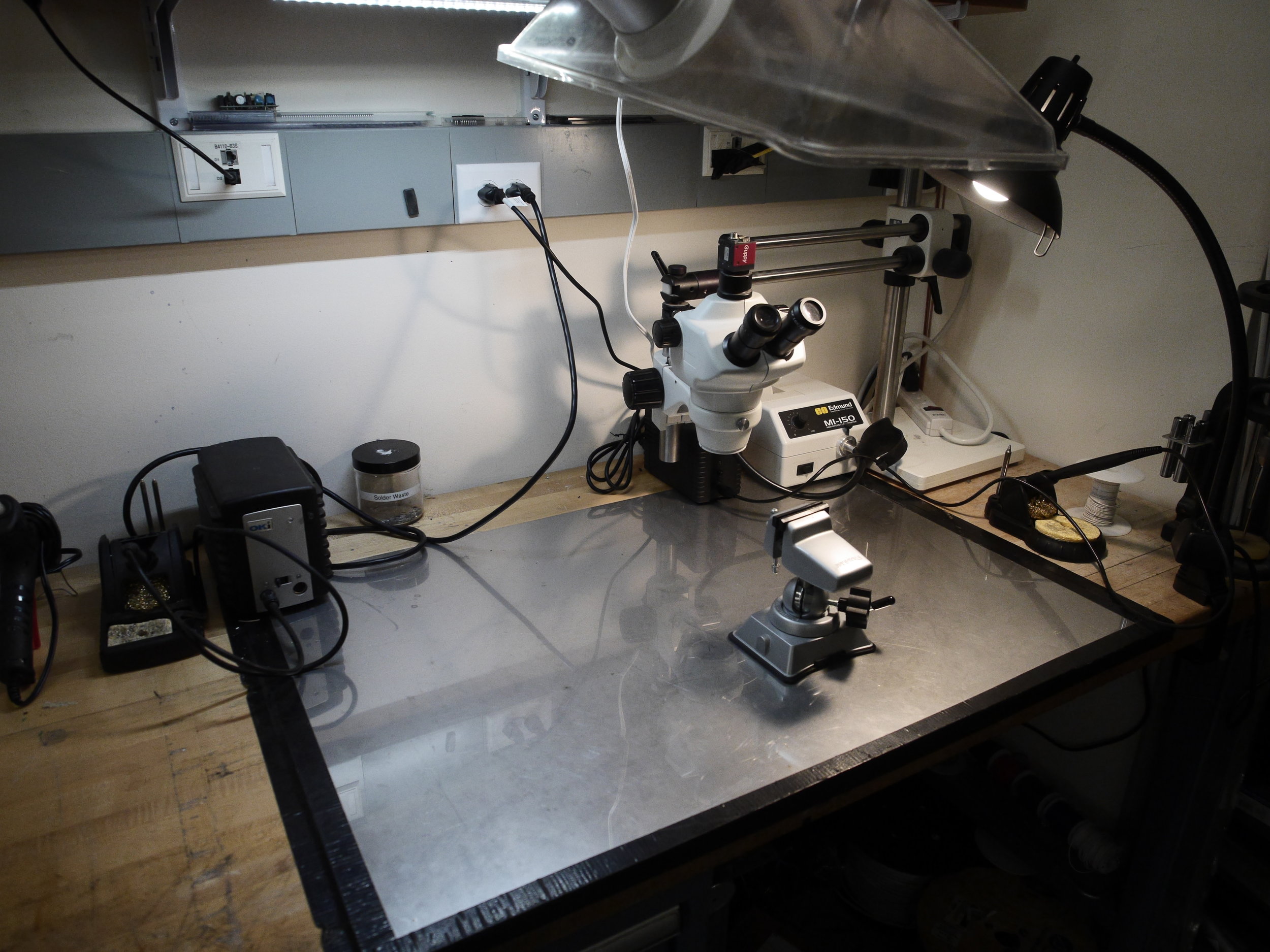

Soldering and rework stations

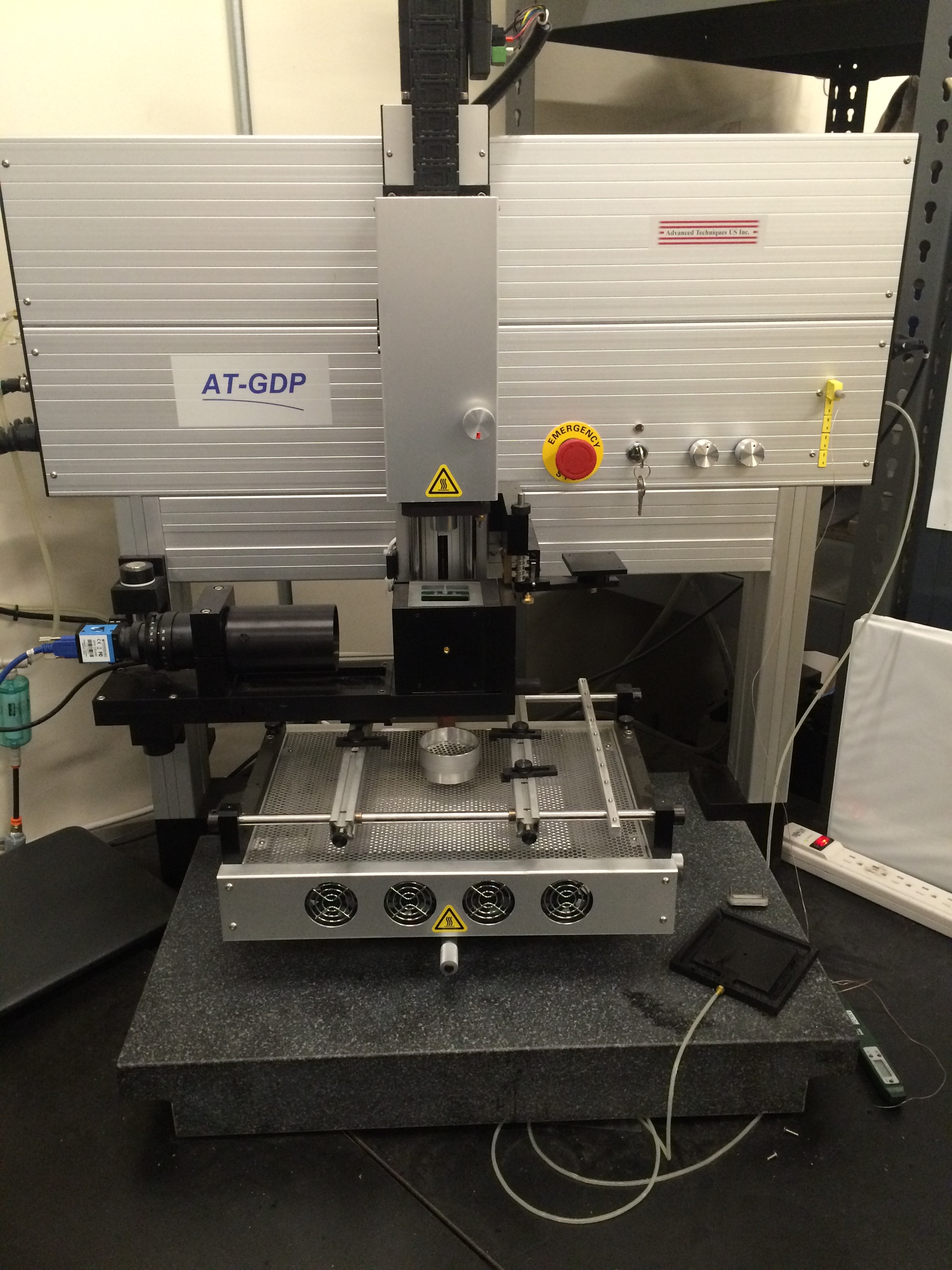

BGA soldering aligner

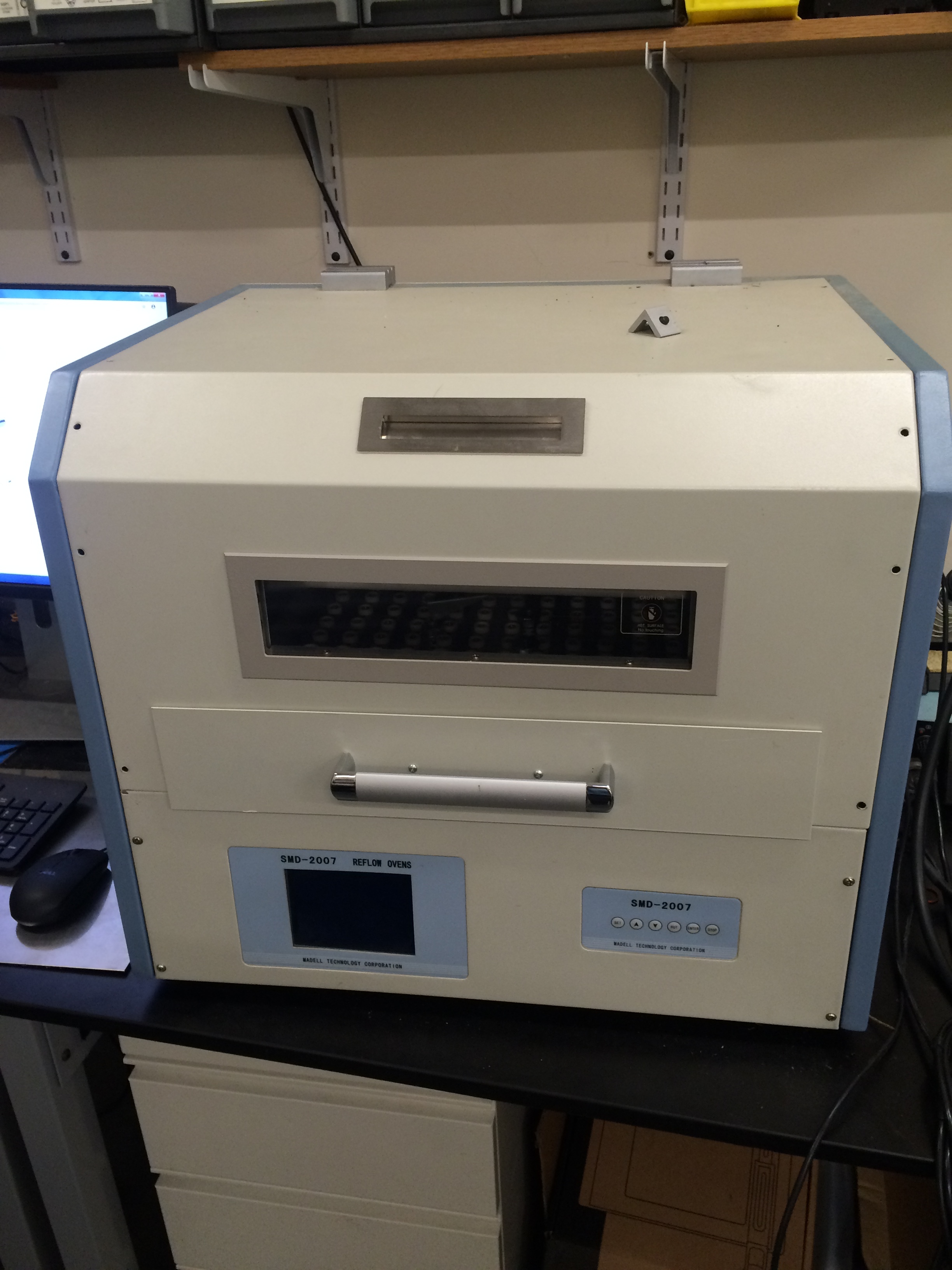

Reflow oven

Stereoscopes

Oscilloscopes, power supplies, function generators

Extracellular and patch amplifiers

Micromanipulators

Optical spectrum, wavefront, power and profile measurement tools

Femtosecond auto-correlator

Lenses, mounts, cameras, PMTs, illumination sources

Prototrak DPM2 CNC mills

Haas CL-1 CNC lathe

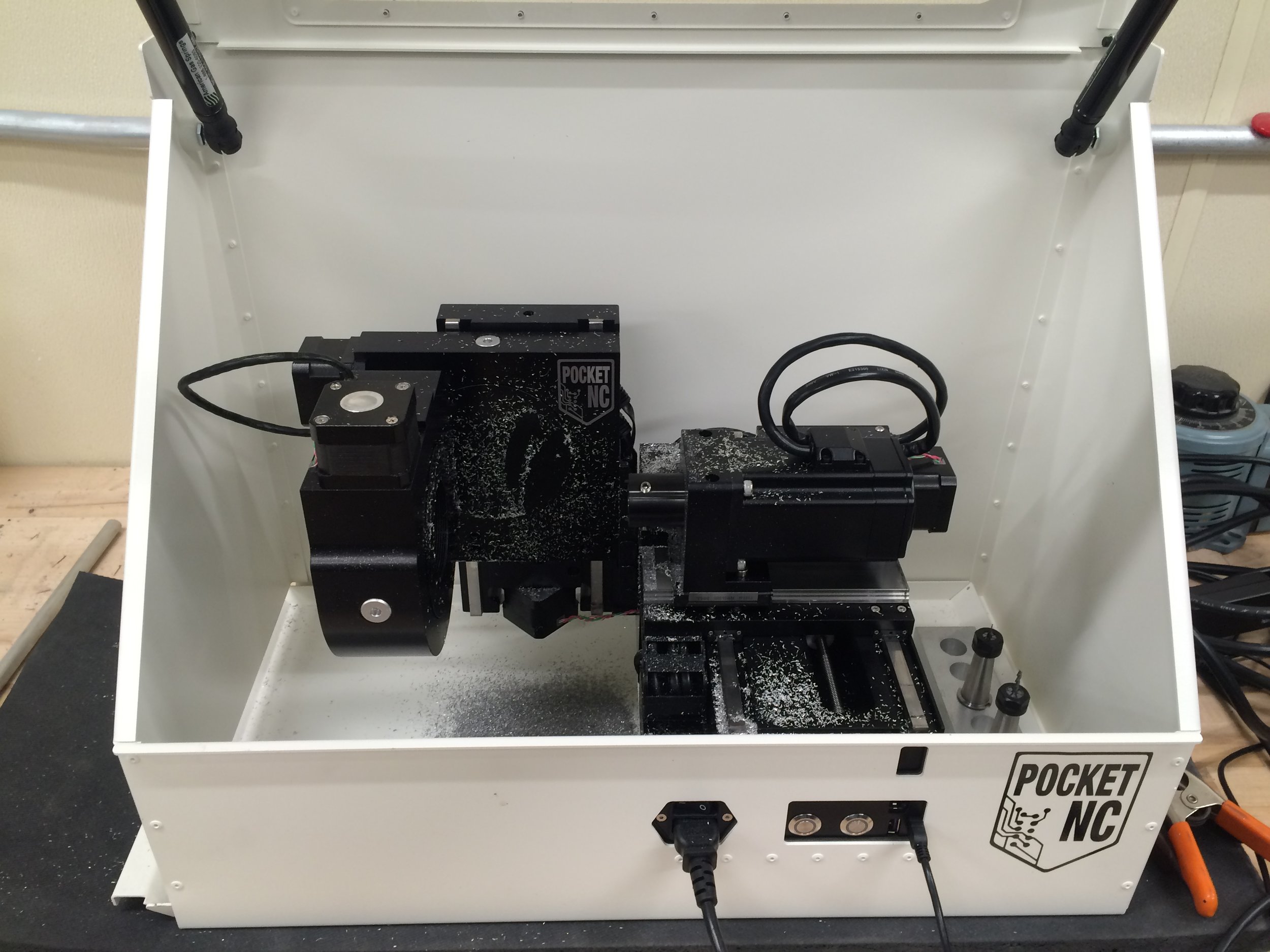

Pocket NC v2 5 axis CNC mill

Hardinge manual lathe

Maxiem waterjet cutter

Orion laser and microtig welders

Thermoformer

Horizontal and vertical bandsaws

Sandblaster

Power sander

All power tools require a ‘buddy’ to be in the shop with you that is capable of calling for help in case of emergency. These include:

Horizontal and vertical bandsaws

Power sander

Panel saw

Drill press

Manual and CNC mills

Manual and CNC lathes

Bench grinder