box Arena design with aluminum extrusions

Box arena is a widely used equipment to study animal responses toward novel environment and open spaces. These arenas, typically fabricated with acrylic panels, often require adhesives to join the panels. And as a result, once assembled, the arenas would have corners that could be hard to clean. It also becomes challenging to modify each individual panel once all parts are joint together.

In this page, we present an open box design without cutting joints on acrylic panels or using adhesives. Our box design utilizes aluminum extrusions as framing material and acrylic panels as walls. We also provide .stl files of 3D printed clips that are compatible with aluminum extrusions for assembling the box. Once assembled, the box will have clean inside corners, and each panel can be taken out for thorough cleaning or modification. Lastly, we also provide an online calculator for those who are interested in fabricating the box. The calculator takes the box size as input, and calculates the dimensions of the materials needed.

Aluminum Extrusions - What are they

Aluminum extrusions, also known as 80-20s, are widely used in engineering designs as a versatile framing solution to configure guards and enclosures. The aluminum extrusions come in different sizes and typically have rail profiles on all sides. These rails provide design flexibility such as adding different accessories to the design. The aluminum extrusions can be easily cut into different lengths. Typical accessories of aluminum extrusions include brackets, linear bearings, hinges, pivots. Aluminum extrusions can be purchased online such as https://8020.net/ or https://www.mcmaster.com/

Box arena with aluminum extrusions

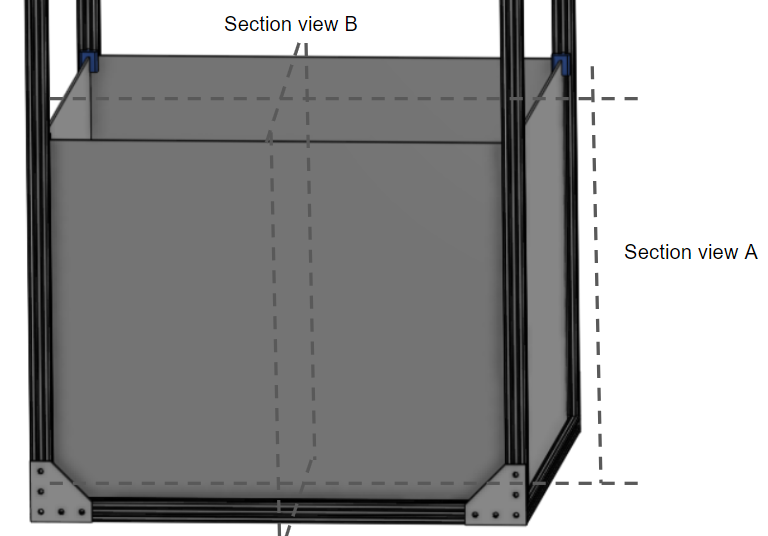

Full view

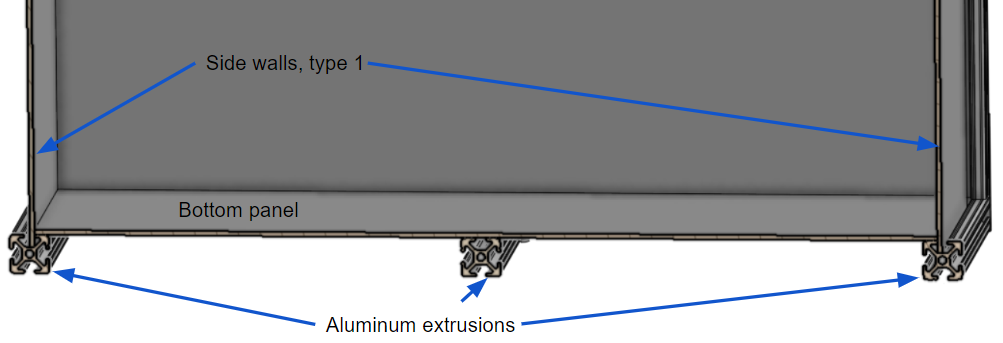

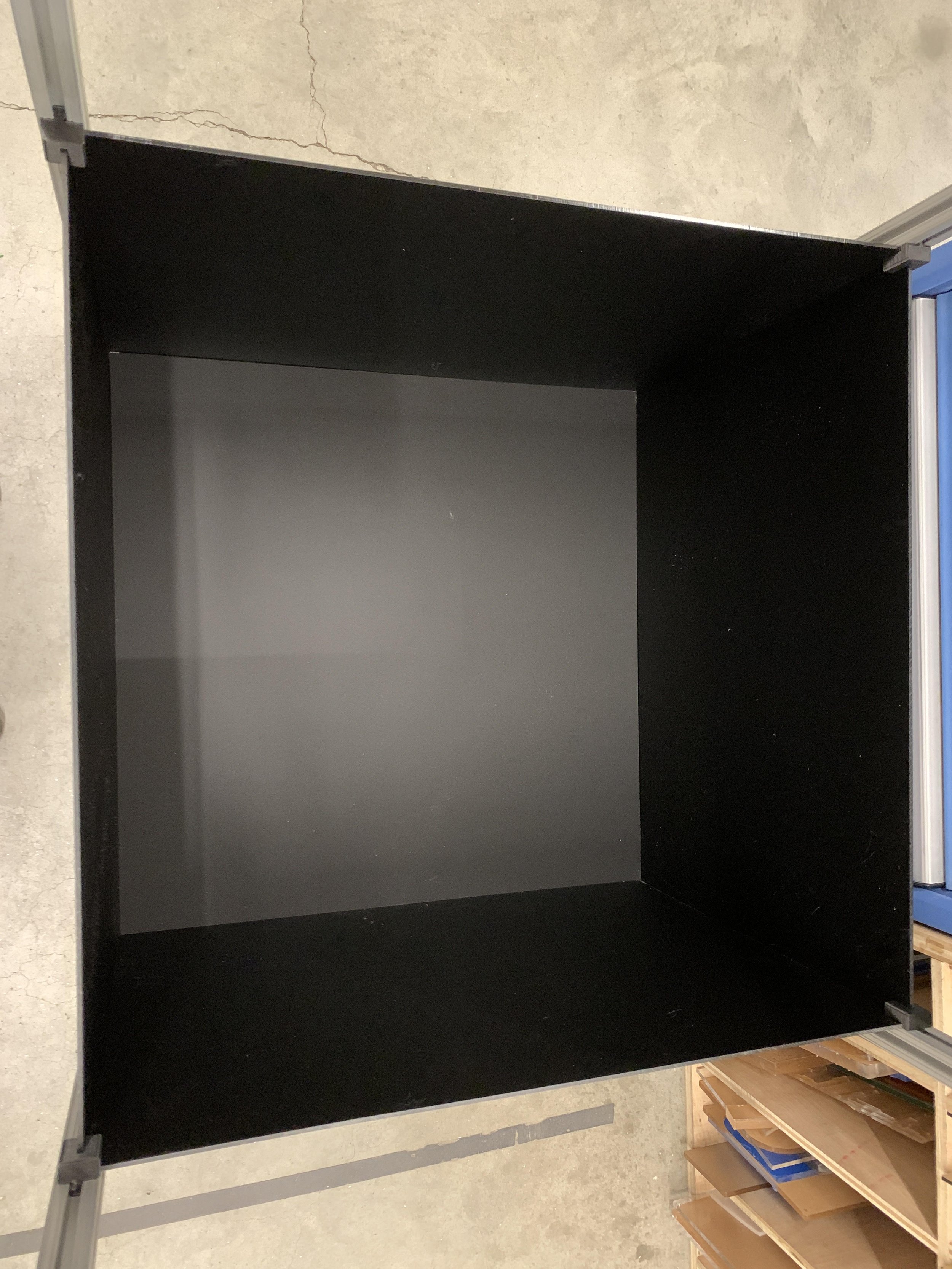

Bottom panel

Section view A: The bottom panel rests on the top surfaces of 2 aluminum extrusions. If the box is large in size, a third aluminum extrusion can be added in the middle of the box for further support.

Wall type 1 (quantity needed: 2)

Wall (type 1)

Walls (type 1) sit in the rails of aluminum extrusions.

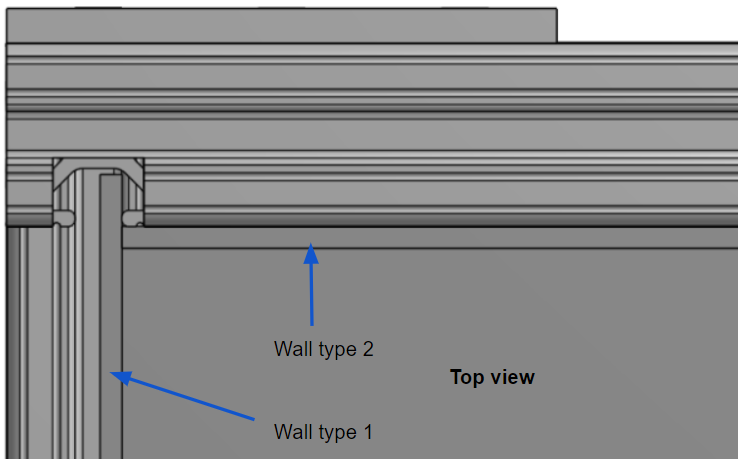

Wall type 2 (quantity needed: 2)

Wall (type 2)

Section view B: Walls (type 2) rest on the same aluminum extrusions as the bottom panel.

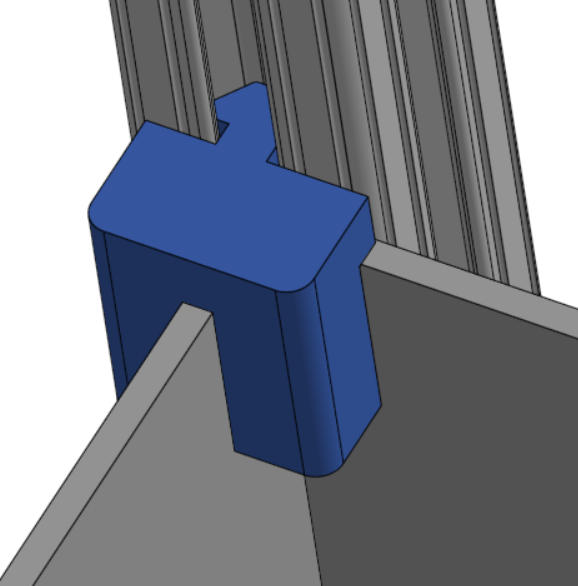

Clips

Clips

3D printed clips are used to fix the walls in the upper corners of the box.

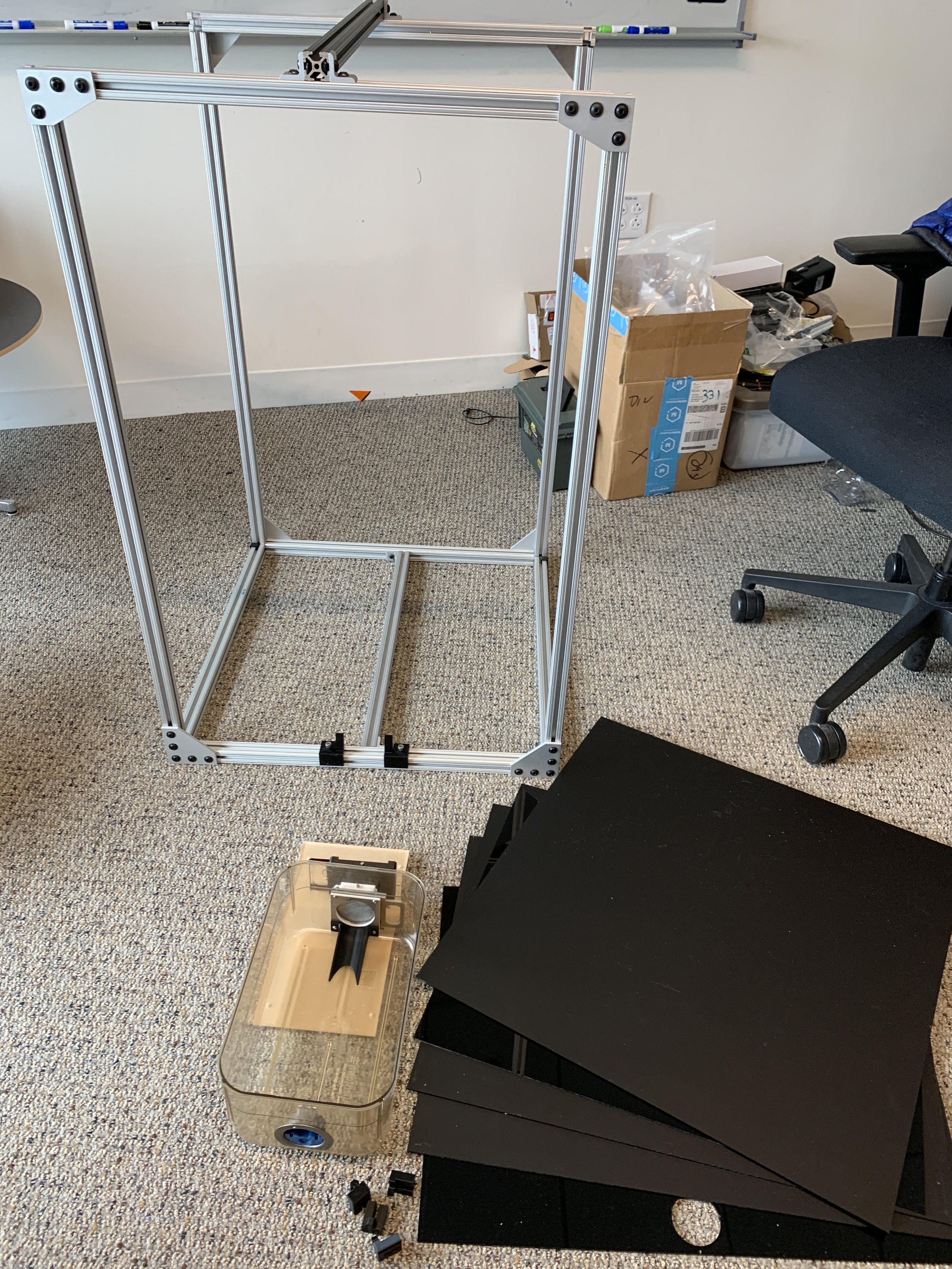

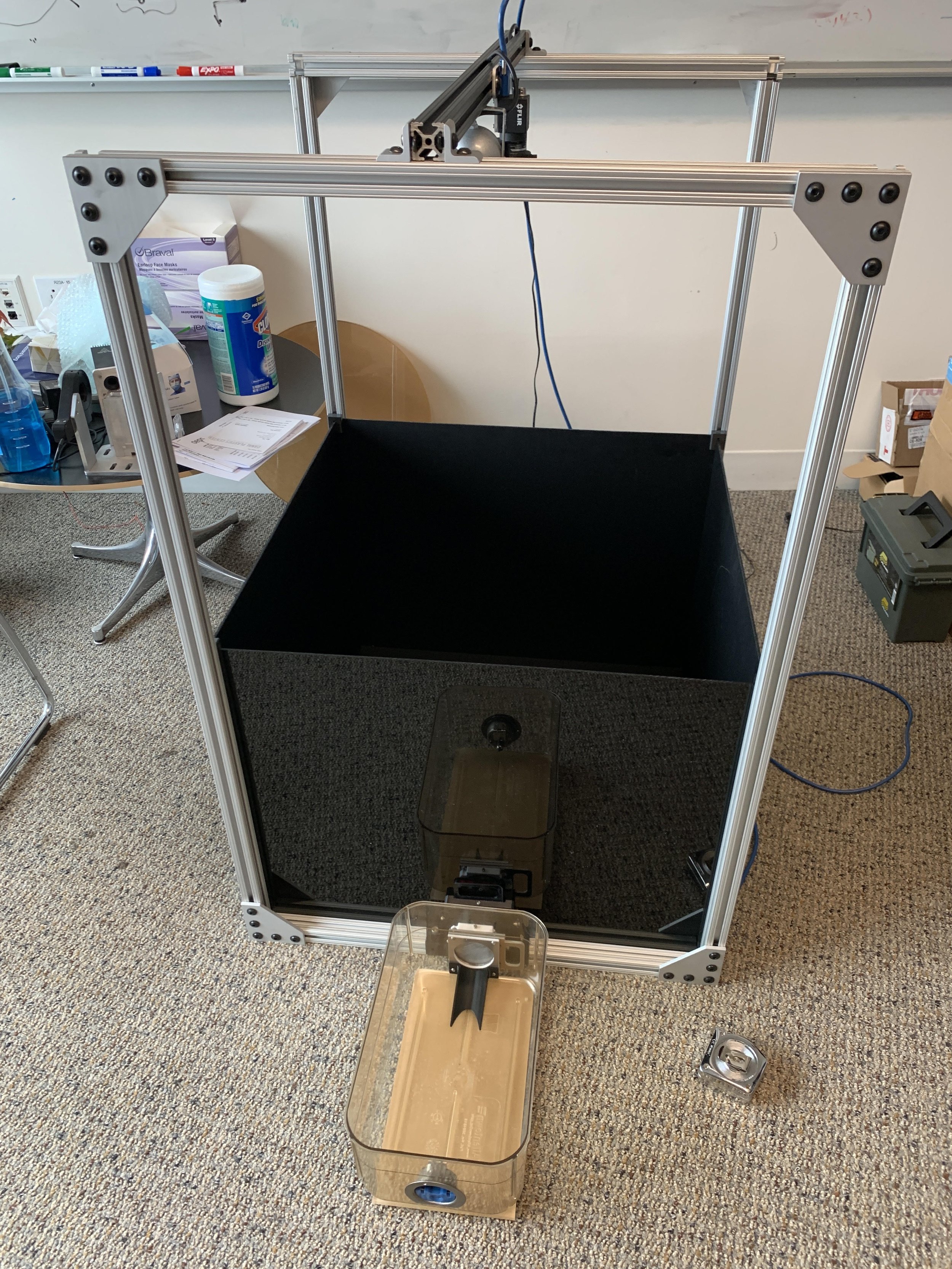

Example box

Before assembling the panels

The aluminum extrusions were first assembled with angle brackets and corner brackets.

Assembled box

3D printed clips

3D printed clips are used to hold the top corners of the box.

Top view of the assembled box

Pros and Cons of our box arena design with aluminum extrusions

Benefits of the new box design include:

No adhesive is required for assembling the box.

Each acrylic panel can be taken out for further modification, such as cutting a hole for a mice entrance.

Can be easily disassembled for thorough cleaning.

Aluminum extrusion frames can be easily configured for mounting additional equipment such as lighting and camera.

Can be easily customized into any size.

Disadvantages:

This design is based on utilizing aluminum extrusions for framing. As a result, this new design could cost more than boxes made with only acrylic panels. When planning the budget, one should factor in the cost of aluminum and brackets.

Aluminum frame’s dimensions such as length and squareness are critical.

A 3D printer is needed for fabricating the clips.

Calculator

Planning to make your own box arena with aluminum extrusions? Please feel free to utilize the calculator below to find out the size of the materials needed. This calculator assumes you are using aluminum extrusions with 1” by 1” cross section.

.STL files for Clips

For 1/8’’ acrylic panels and 1’’ aluminum extrusions. You will need 2 for each type below:

.STL file for foot clamp (0.118” thichness panels, 1” by 1” cross section aluminum extrusions)

You can 3D print and use these foot clamps for holding acrylic panels (type 1) in places. They clip on the aluminum extrusion and pushes the acrylic panels towards the bottom panel.